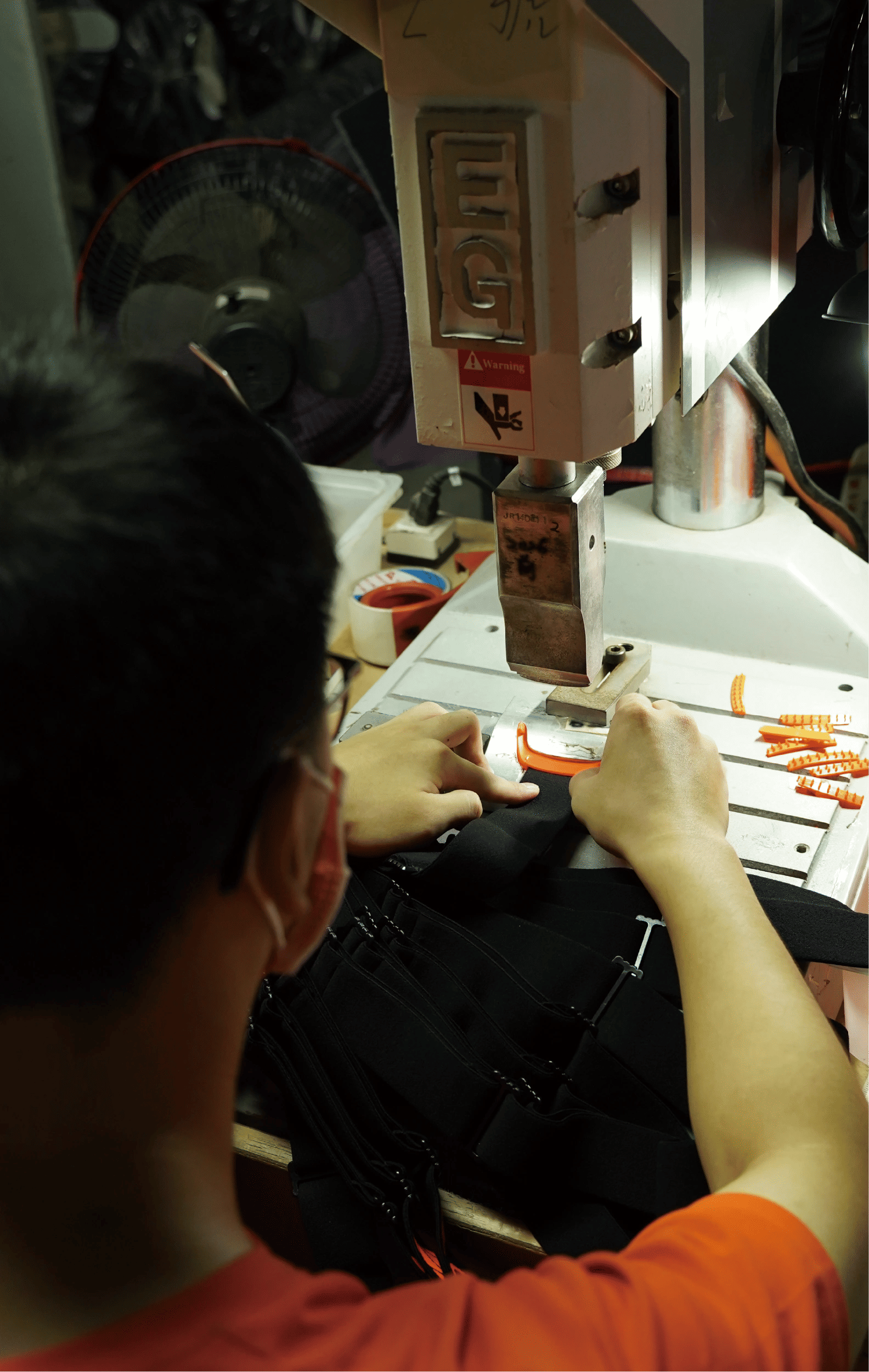

Yi-Chia-Hsin Enterprise has 20 years of experience in R&D and manufacturing, and has been deeply rooted in the market for many years, committed to providing diversified customized services. Compared to simple industrial services in the past, with the advancement of technology and innovation, we can provide customized services such as foam material selection and size adjustment based on the characteristics and specifications of customer products to create products that best meet customer needs. Through in-depth communication and R&D, we can produce products with unique value and functionality while still maintaining a competitive advantage in large-scale production. Choosing to cooperate with us, you will receive professional services and quality products that meet your expectations.